7. Setting the datum portion

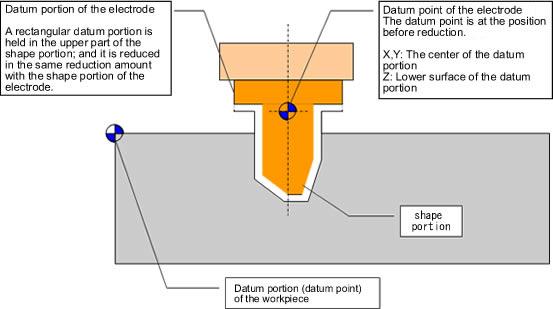

When you use an electrode to process a workpiece by EDM, you must clarify the relation between positions of the electrode and the workpiece. The coordinate position for this is called "a datum point" and the part where the datum point is set is called "datum portion". The position data of the "datum point" of the electrode to that of the workpiece must be instructed as a design value before machining. In addition, the "datum portion" of an electrode largely influences efficiency of centering work on an EDM, and it is necessary to design it in the shape that is considered about efficiency of centering work.

1) "Datum portion" of an electrode

"Datum portion" is prepared separately from the shape portion. Generally, it is prepared in the upper part of the shape portion with a simple rectangular shape and is set as a "datum portion ". At the time of the electrode production, it is necessary to adopt a cutting method that decreases occurrence of the position accuracy error of "datum portion" to the shape portion. Particularly, a position error occurs when you cut the lower surface of the datum portion with a different tool from the shape portion. To prevent this, it is necessary to identify the necessary part of the "datum portion" for centering and to process it at the same time with the same tool with the shape portion.

2) Reduction for "datum portion"

The lower surface of the "datum portion" is used as a datum surface of the Z direction at centering work. Please reduce it in the same way with the shape portion at the time of the electrode production. Without reduction, you need to change the order value of machining depth at EDM depending on the amount of reduction, and a problem occurs that the program of EDM becomes complicated.