9. How to think about multi-electrode

A unified electrode to simultaneously process plural machining areas which are objective of EDM is called a multi-electrode.

The following points are the elements to think about a multi-electrode.

- It is a machining area of plural same shapes and each machining accuracy and finish surface roughness should be equalized.

- You want to reduce the number of electrodes and to shorten setup time.

1) The advantageous points of multi-electrode

(1) The same machining accuracy and finish surface roughness are provided in each machining area.

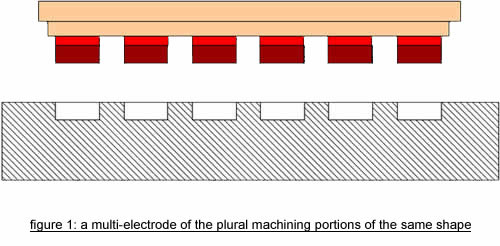

As shown in Figure 1, it is difficult to gain uniform machining accuracy and finish surface roughness in plural machining areas of the same shape, and it takes longer time to adjust them, but it becomes easier by a multi-electrode.

(2) The setup time can be shortened by reducing the number of electrodes.

A multi-electrode helps large shortening of setup time because it gets longer in proportion to the number of electrodes.

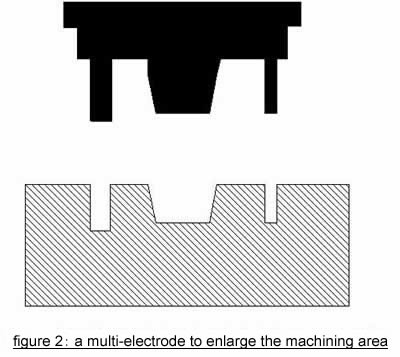

(3) It makes rough machining speed faster.

As shown in Figure 2, by moderately enlarging the machining area, rough machining conditions of higher current value can be used, and it may be able to shorten rough machining time. Especially when the electrode material is graphite, it is necessary to reduce the machining conditions by being limited to a small machining area, and the effectiveness of a multi-electrode may increase.

2) The disadvantageous point of multi-electrode

(1) If the machining area becomes large, the machining accuracy declines, and the finish surface roughness turns worse.

As described in Figure 2 and 3 of Item 8 "How to think about division", the machining accuracy and finish surface roughness worsen if the machining area becomes larger. Therefore, you have to avoid unnecessarily making the electrode multiplied.